02.09.25

Quality assurance in clean rooms

Cleanrooms play a central role in numerous high-tech and healthcare industries. Whether in pharmaceuticals and biotechnology, medical technology or microelectronics – wherever even the slightest contamination can have serious consequences, a controlled production environment is essential. Quality assurance is at the heart of all measures. It ensures that products not only comply with legal requirements but also meet the highest safety and reliability standards.

Why is quality assurance important?

The importance of quality assurance in cleanrooms stems from the risks that even the smallest deviations can cause. In pharmaceutical or medical technology, microbial or particulate contamination can impair the effectiveness of drugs or cause life-threatening infections (patient safety). In microelectronics, on the other hand, particles measuring just a few nanometres can destroy the function of entire components (product safety). International standards such as GMP (Good Manufacturing Practice) and ISO 14644 require strict controls, compliance with which must be documented in a verifiable manner (Legal and regulatory compliance). Furthermore, deficiencies in the quality process not only lead to product recalls and damage to reputation, but also to enormous costs (Economic efficiency). Quality assurance thus forms the basis for trust, safety and sustainable economic success.

How is quality assurance guaranteed in clean rooms?

Implementation is achieved through an integrated system of controls, rules and behaviours that encompasses all levels of an organisation. Key elements include:

Cleanroom classification and monitoring:

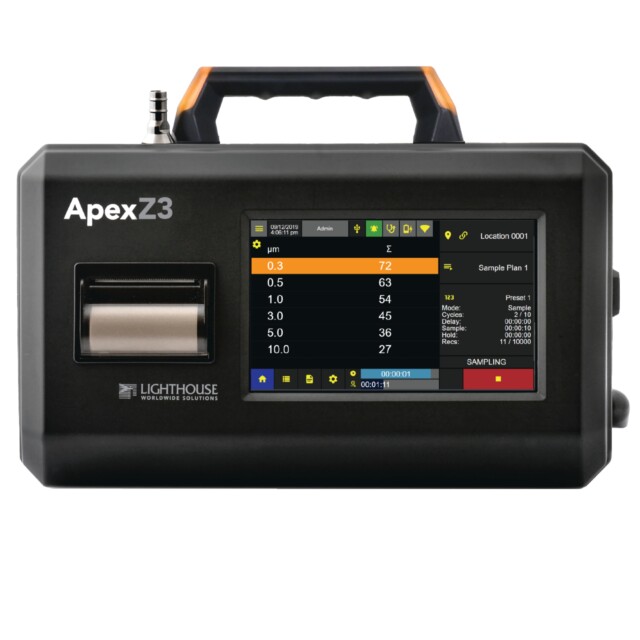

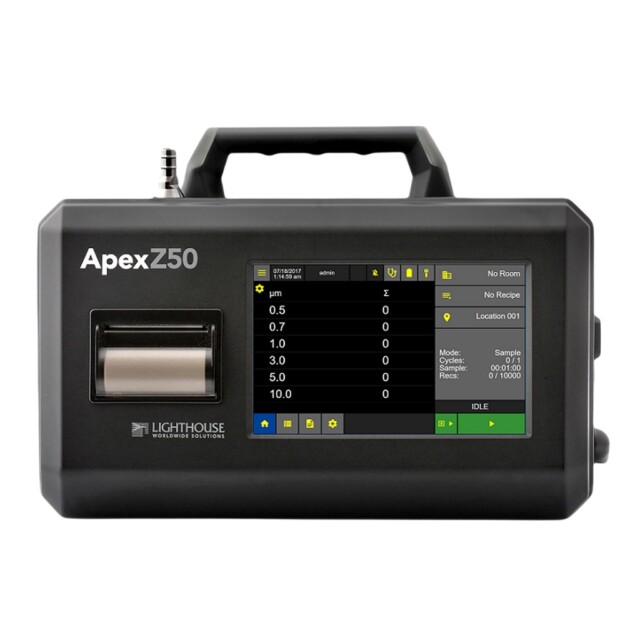

Cleanrooms are classified according to ISO 14644 based on the concentration of airborne particles. To ensure compliance with these specifications, particle counters, airborne germ collectors and modern sensor systems are used to enable continuous monitoring of cleanroom conditions.

Hygiene management:

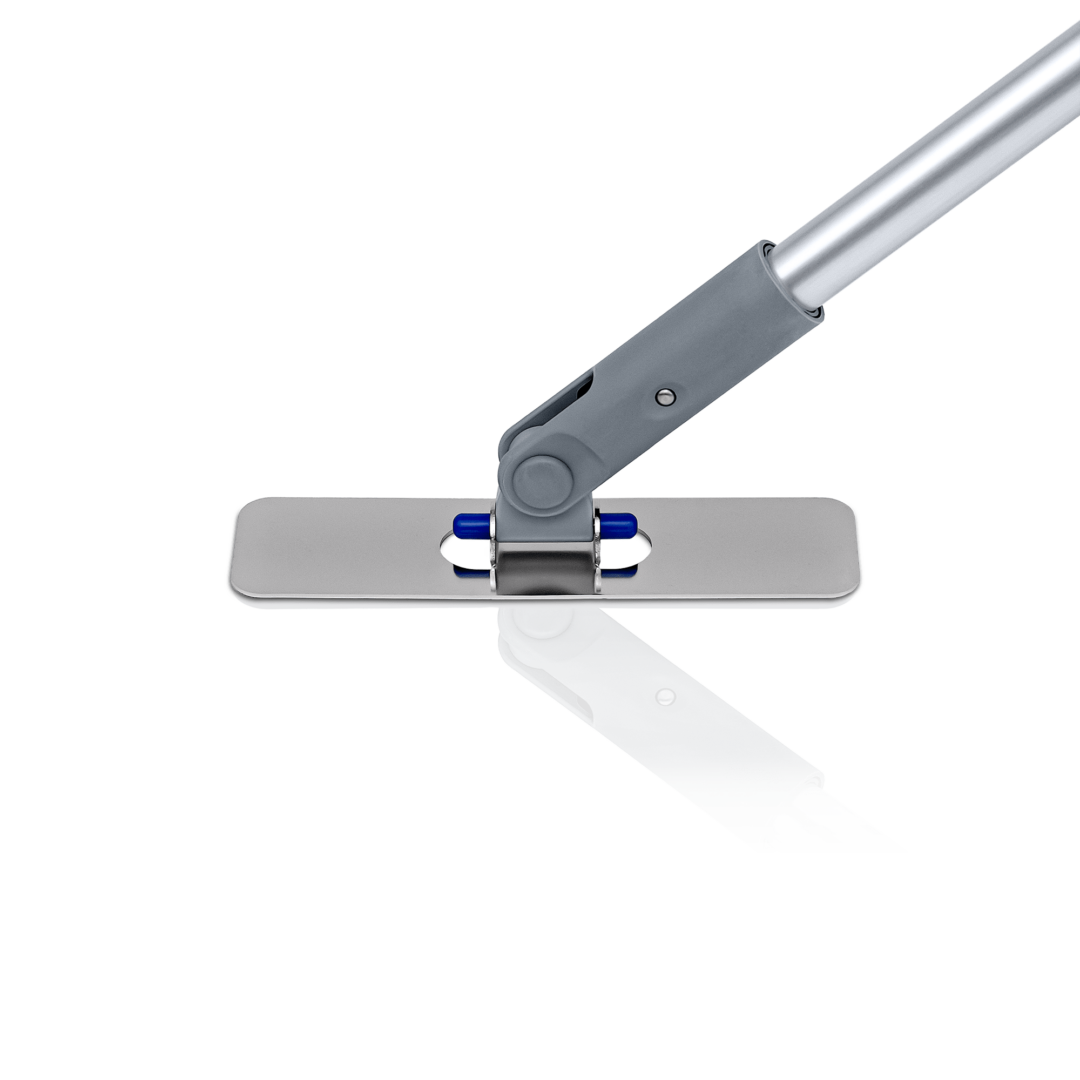

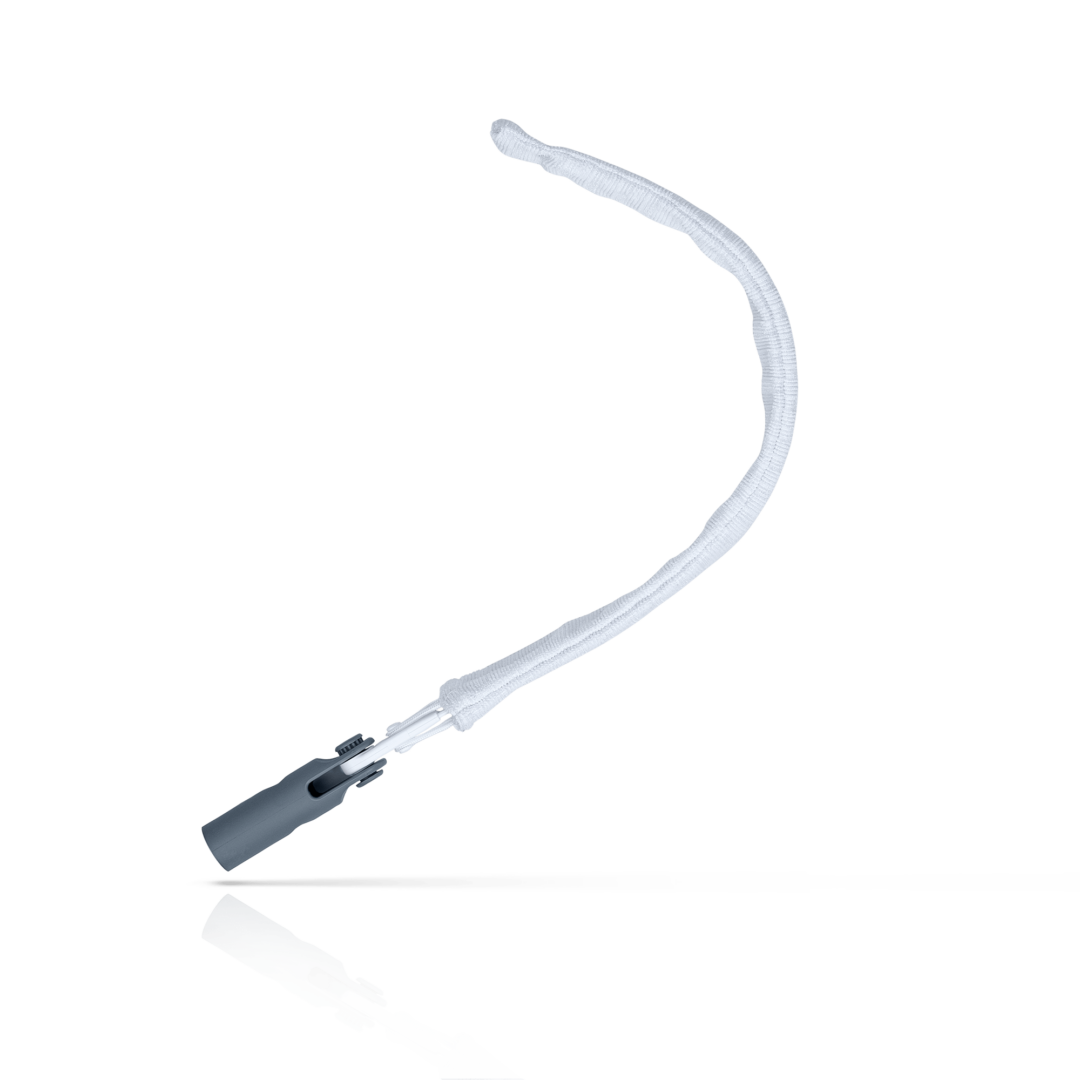

To prevent contamination, validated cleaning and disinfection procedures are carried out regularly. Rotation principles are applied when selecting disinfectants in order to minimise the development of resistance and ensure the long-term effectiveness of the measures.

Staff training:

Since humans are the biggest source of contamination in cleanrooms, comprehensive training is essential. This includes learning how to put on and take off cleanroom clothing correctly, complying with hygiene rules and being familiar with GMP requirements. Regular re-qualification ensures that staff continue to meet the required standards.

Validation and qualification:

All equipment, processes and cleaning procedures used must be demonstrably suitable for their respective purposes. This is ensured by the three steps of qualification – installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ) – which guarantee that systems operate reliably and in compliance with regulations.

Documentation and traceability:

Legally required, complete records are a central component of quality assurance. All cleaning plans are documented in logs or logbooks and are crucial for the daily monitoring and maintenance of cleanroom conditions. Electronic systems such as the electronic batch record (eBR) help to avoid errors and ensure traceability and auditability.

How is quality assurance managed?

Quality assurance management in cleanrooms follows a holistic approach. Quality management systems (QMS) define binding processes, responsibilities and control points. Risk management in accordance with ICH Q9 identifies critical process steps and defines preventive measures. Deviation management and CAPA (corrective and preventive actions) not only ensure that errors are rectified, but also that sources of error are avoided in the long term. Regular audits and inspections by internal departments and external authorities ensure compliance with all requirements.

In summary:

Quality assurance in cleanrooms is much more than a legal obligation. It is an essential component of product safety, patient protection and the economic stability of companies. Strict classifications, continuous monitoring, qualified personnel and a robust quality management system ensure that cleanrooms fulfil their central task: maximum purity and safety for the most sensitive products of our time.