27.04.23

The development of an innovation in cleaning: Granuline

Overdosing consumes billions of dollars in costs each year in the cleaning industry. That's why Wetrok set itself the following goal: to develop a cleaning agent that cannot be overdosed. Years of research went into developing a new form of cleaning agent. The result: granules - packaged in individual portions.

The core of modern cleaning

Modern cleaning is not an isolated activity, but a holistic process. In the past, there was only one requirement for a cleaning product: it had to clean properly. Today, the requirements are much more complex: customers are interested in how easy the product is to use, how safe it is for staff, how it is transported and what impact it has on the environment. They want to take responsibility for their employees and the environment. With the granulate, a solution has been found to meet all of these requirements better than any liquid detergent.

The development of Granuline

Product development always starts with a customer problem. Here, the biggest problem in the industry was tackled: overdosing. The aim was to develop a product in which cleaning staff are completely relieved of the task of dosing. This means: no manual dosing action, no dosing system. The cause of overdosing lies not only in the widespread misconception that “the more product, the cleaner”, but often also in a modest knowledge of mathematics. Many cleaners have great difficulty calculating when dosing. For example, if the task is to add 5 % of a cleaning agent to a liter, some cleaners are already unsure whether the cleaning agent should make up 5 % of the liter or whether they have to add the 5 % to the liter. With Granuline, such preliminary work and stumbling blocks are now completely eliminated.

Wetrok Granuline comprises five granular cleaners for ecological cleaning of the entire building:

- GRANUSURF (surface cleaner)

- GRANUSAN (sanitary maintenance cleaner)

- GRANUSAN FORTE (basic sanitary cleaner)

- GRANUBOWL (WC cleaner)

- GRANUFLOOR (floor maintenance cleaner)

The right shape

At first glance, powder or a tablet in a dissolvable film seems obvious – after all, this is already familiar from machine dishwashing or textile washing. However, hot water, a certain soaking time and an automatic washing program support the dissolution. These supportive factors are not available in commercial cleaning: the cleaning essence must be ready for use immediately without reaction time, without agitation and with cold water. In this respect, tests with powder or a powder-pressed tablet showed either insufficient dissolution or too long a dissolution time. Important lesson: what does not dissolve completely does not clean optimally.

The synergy of innovative technology and highly effective raw materials (patent)

After intensive research, an analogy was found in another industry. In tunnel construction, polymers are used in the walls. These are placed around the stones and release certain particles that are not wanted at this point. These are then held in suspension. If this works with the removal of unwanted particles in tunnel construction, why not with the dirt to be removed?

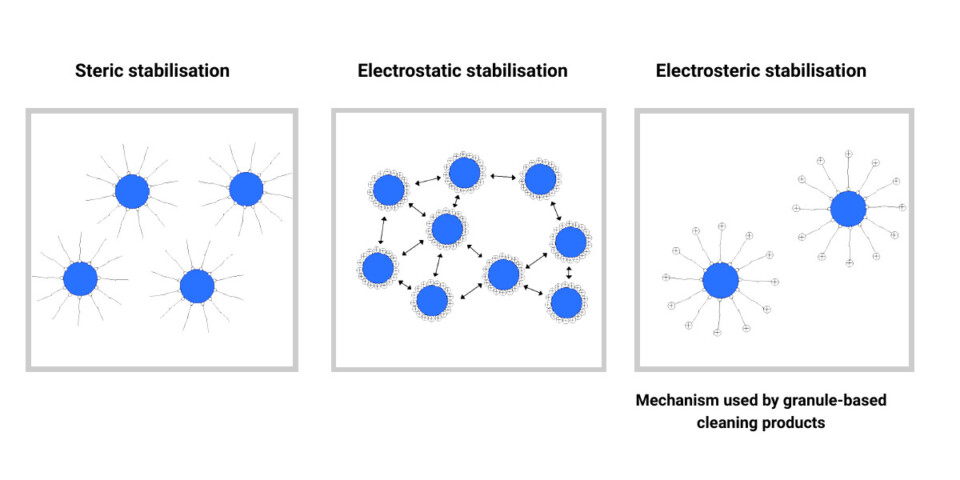

The process is called electrostatic stabilization and is a combination of steric and electrostatic stabilization.

Electrosteric stabilization is about the ionic “character” of the connecting chains: one end leads to the grain, one end to the water. This means that only connecting ends with the same ionic charge (positive in the illustration) protrude into the water – these repel each other. This repulsion keeps the dirt in suspension for a while and prevents it from sinking back to the bottom. This benefits the cleaning process. The interaction of charge and chain length results in raw materials that are called anti-redeposition agents.

In addition to the electrosteric effect, a special raw material has been added to the granulate, which further enhances the cleaning performance, because thanks to this not only emulsifiable, but also the smallest dirt particles (e.g. fine dust) can be loosened in hard-to-reach places. The special raw material extremely lowers the surface tension and enables the cleaning solution to penetrate even the smallest cracks and fissures. This time-to-value, measured using tensiometric analysis, is still unique today – and it was precisely this technological leap that was rewarded with the patent for Wetrok Granuline.

Environmental aspects of granuline

The environmental advantage of granuline lies in its form: granules. The main problem with transportation is that far too much – completely unnecessary – water is transported worldwide, namely the water in liquid detergents. The granulate eliminates the water and only the core active ingredient for cleaning, the granulate, is transported. Instead of six trucks of liquid chemicals, only one truck of granules is needed. There is also no need to return empty containers. What a huge impact on costs and CO2 emissions. During the utilization phase, this means a reduction of around 75 %.

In the calculation of emissions from granuline (cradle-to-grave method), a direct comparison of granuline and liquid detergent concentrates also showed emissions to be 19 % lower (ClimatePartner has confirmed this). Raw materials, production, inbound and outbound logistics, packaging, disposal and overhead emissions were all taken into account. This was rewarded with the “climate-neutral product” label from ClimatePartner. Further efforts to reduce emissions even further are already being implemented. Emissions that cannot be reduced any further are offset by a recognized climate project.

As there is no water in the product, there is no need for 100 % preservation. This is a pioneering contribution to environmental and water protection. Today, it is not known how many tons of liquid detergents are thrown away worldwide after use with the biocide content intact.

The manual foam cleaning method also conserves water resources. Compared to the conventional bucket-and-cloth method, an additional 90% of water is saved. Sustainable product and sustainable method go hand in hand.

The 7 environmental benefits of Wetrok Granuline:

- climate neutral

- very good biodegradability according to OECD 302 b.

- not preserved

- VOC-free

- 90 % lower water consumption (when used with the foam method)

- 9 % lower CO2 emissions (compared to liquid cleaners)

- No overdosing possible (pre-dosed sachets)

Health aspects of granuline

There are no more 10-liter canisters to be heaved into the storage racks or laboriously lugged around the building, just lightweight granulate sticks. Thanks to the perforated, easy-to-open stick, there is also no risk of skin contact with the granules – even if you forget your gloves without permission. There are also no solvents, which many liquid cleaning agents contain, in the granules – so no harmful vapors can enter the respiratory tract.

Summary

Granuline meets all the important requirements of a modern cleaning agent in terms of climate protection, high cleaning quality and safe processes.

Find out more about Wetrok Granuline: www.granuline.com